- Siemens prosave 6 serial#

- Siemens prosave 6 driver#

- Siemens prosave 6 pro#

- Siemens prosave 6 series#

In addition to transmitting the fault message via binary output contacts, all status messages can be called up individually on the display or through the serial interface. The purging function in the event of a device failure, prevents the accumulation of toxic, corrosive, or explosive substances inside the device. In the event of non-ignition, an alarm is triggered and the gas supply is automatically switched off by a solenoid valve. If the detector flame goes out accidentally, it is automatically re-ignited. After automatic start at the end of the warm-up phase and automatic measurement operation, a controlled self-monitoring function takes place. Special attention was paid to safety functions. The high, adjustable operating temperature for the sample gas channel and detector also facilitates the measurement of high-boiling mixtures and the measurement of hydrocarbons at water vapor concentrations of up to 100%. A requirement for the latter application is the use of a filter that is wear-free and corrosion-resistant and the use of a quartz capillary as the measuring gas capillary. Almost every application can be executed, from trace hydrocarbon monitoring in high purity gases, which is made possible by high resolution and small differences in response factors, to total measurements of hydrocarbons in the presence of corrosive gases. The variants of the FIDAMAT feature a wide range of applications.

Siemens prosave 6 series#

The two sensors differ in the electrode material and react differently to flammable accompanying components.īoth variants are characterized in particular by their high linearity and also offer all the advantages of the Series 6, such as the intuitive operating concept and the open interface architecture. This results in a potential difference between the two electrodes, which is a measure of the oxygen concentration in the sample gas.ĭepending on the application, a catalytically inactive ZrO2 sensor and a catalytically active ZrO2 sensor are available.

Since ZrO2 is electrically conductive at 650 ☌, an ion migration occurs towards of the lower partial pressure.

Due to the concentration differences on both sides, there is partial pressure that differs. The outside of the sensor is exposed to ambient air acting as a reference electrode. The sample gas flows through a tubular sensor which is heated to 650☌ at a constant flow rate. The OXYMAT 64 operates with ZrO2 sensors. Moreover, the field device design is also the basic variant for the optional heating feature of the analysis unit for measuring any low-boiling components and for use in hazardous zones Gas-tight separation of the electronic and physical components when using the field analyzer design with class IP65 protection and a purging gas connection guarantees a long lifetime even under harsh ambient conditions. The detector unit has no contact with the measuring gas, thus allowing it to be used under harsh conditions while guaranteeing a long service life at the same time. High-quality materials in the gas channel even enable the analytical devices to be used for measurements of corrosive gas mixtures. This guarantees perfect linearity and enables parameterization of smallest measuring ranges from 0 to 0.5% (detection limit 50 ppm) up to 0 to 100%, and even 99.5 to 100% in a single device. The OXYMAT 6 measures oxygen using the paramagnetic alternating pressure method. Start the restore framework by tapping the "Start Restore" button.The SIL 2 classification obtained by OXYMAT 6 makes it easier for plant operators to comply with the often required proof of risk reduction. Open the "Restore" menu. Below Open, you open (name of your project.brf).

Siemens prosave 6 pro#

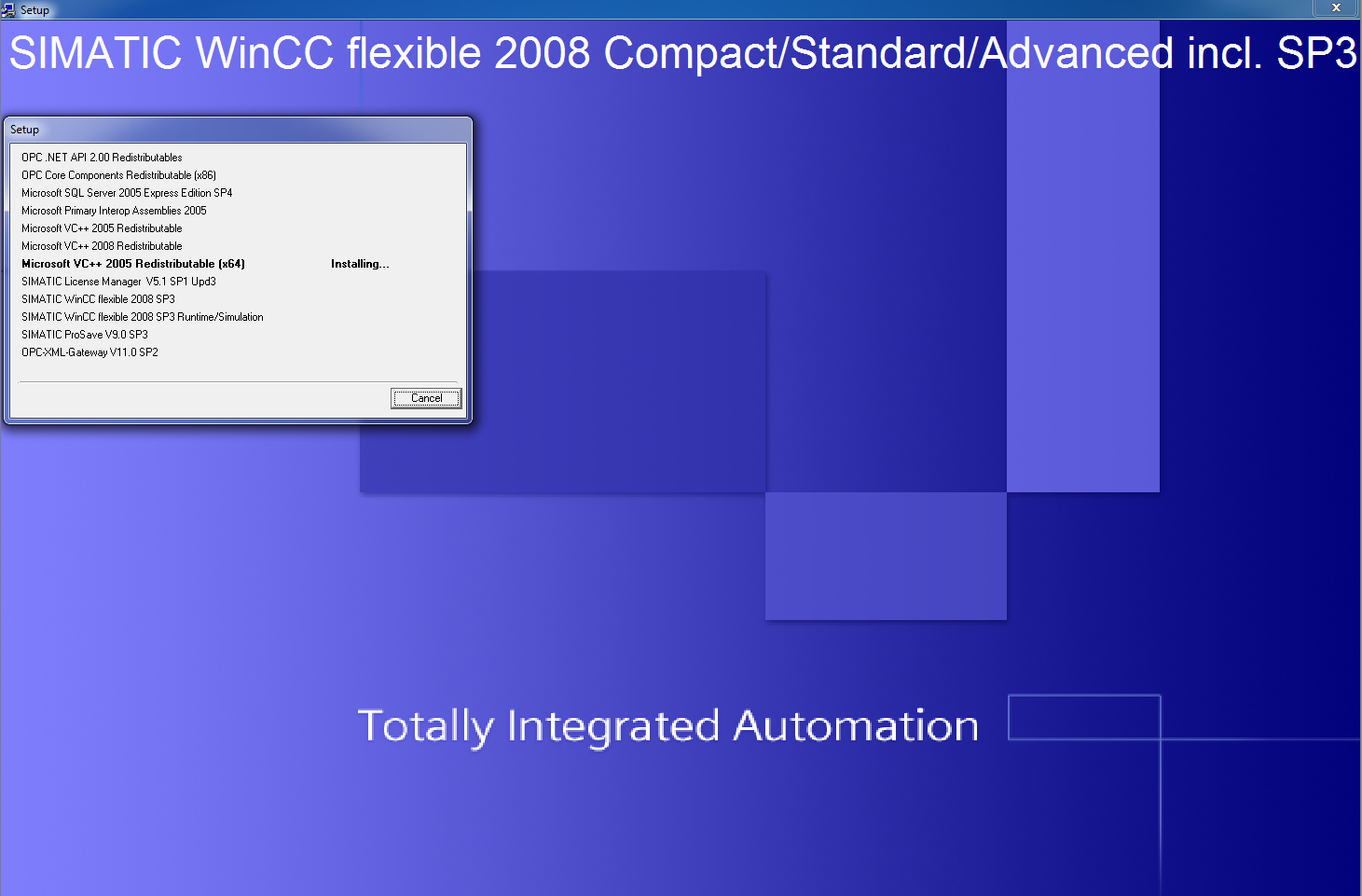

Select the Restore tab and picked the area of the reinforcement record to be by tapping the "… " catch and press the "Start reestablish" Simatic HMI ProTool Pro 6.0 SP3 software is the old Siemens HMI programming software, although it is almost no longer used for new projects, but it is pretty much used for old negative projects.Select the Backup and picked an area for the reinforcement by tapping the "… " catch and press the “Start backup”.we will run Software Prosave,select the SIMATIC HMI model TP700 Comfort and Ethernet as Transfer channel, and insert the IP address 192.1.6.44 of the Device.To determine the address manually, enable "Specify an IP address".192.1.6.44.Answer:The ProSave tool is supplied together with ProTool. Question:How to use the ProSave Service Tool for Siemens OP270 6. Answer:The display of 6AV6542-0CA10-0AX0 Siemens OP270 is 5.7inch,which resolution is 320 x 240.

Siemens prosave 6 driver#

0 kommentar(er)

0 kommentar(er)